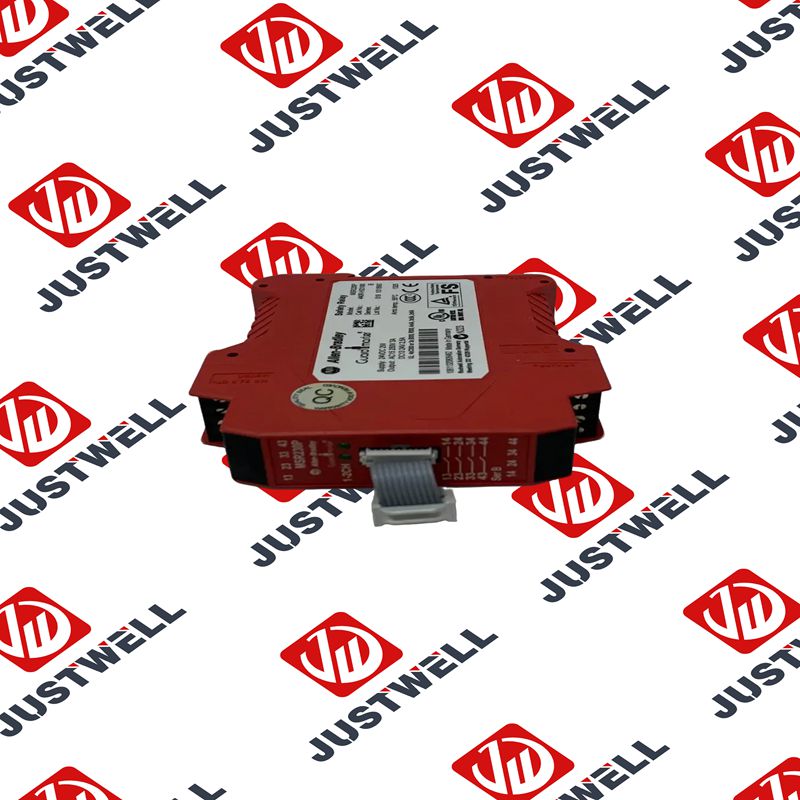

Description

440R-H231180 Allen-Bradley Controller module

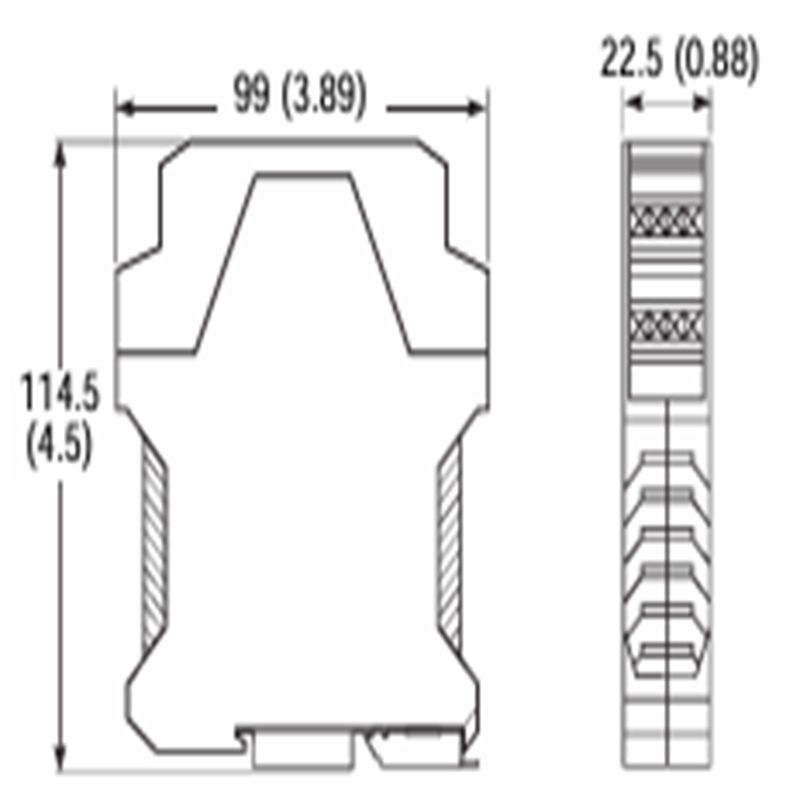

Product Dimensions:

Product Description

The 440R-H231180 is a single-function, dual-channel safety relay. It’s part of the GuardMaster family, known for providing a cost-effective and reliable solution for basic safety applications. This specific model is designed to monitor Emergency Stop (E-Stop) buttons and guard interlock switches (safety gates). It typically features instant and delayed output contacts, allowing for both immediate machine shutdown and controlled stopping sequences.

Product Parameters

Here are the key specifications for the Allen-Bradley 440R-H231180:

- Series: GuardMaster Safety Relay

- Function: E-Stop & Guard Monitoring

- Input Compatibility: Monitors single or dual-channel E-Stop buttons and/or safety interlock switches (e.g., limit switches, magnetic switches).

- Safety Category (EN ISO 13849-1): Up to Category 4 / PL e (Performance Level e)

- Safety Integrity Level (IEC 61508/62061): Up to SIL 3 (Safety Integrity Level 3)

- Safety Outputs:

- Instantaneous: 3 Normally Open (N.O.) safety outputs (often referred to as Force Guided Outputs).

- Delayed: 1 Normally Open (N.O.) safety output with a programmable delay (typically 0.1 to 30 seconds).

- Auxiliary Output: 1 Normally Closed (N.C.) auxiliary output (non-safety related, for status indication).

- Supply Voltage: 24V DC

- Terminals: Removable screw terminals

- Mounting: 35mm DIN Rail

- Enclosure Rating: IP20 (Terminals), IP40 (Housing)

- Operating Temperature: Typically -5°C to 55°C (23°F to 131°F)

- Response Time: ≤ 20 ms (Instantaneous outputs)

Product Advantages

The 440R-H231180 offers significant advantages for machine safety integration:

- High Safety Rating: Achieves up to Category 4 / PL e and SIL 3, making it suitable for applications with high safety requirements.

- Dual-Channel Monitoring: Provides redundant monitoring of safety inputs, which enhances safety by detecting faults within the safety circuit itself.

- Instantaneous & Delayed Outputs: The combination of immediate stop capabilities and controlled delayed shutdowns allows for more flexible and less disruptive machine stops, protecting both personnel and equipment.

- Compact Design: Its slim profile saves valuable space within control cabinets.

- Easy Configuration: Often features simple rotary switches or dip switches for setting delay times and other parameters, simplifying setup.

- LED Status Indicators: Clear LED indicators provide quick visual feedback on power, input status, and output status, aiding in troubleshooting and diagnostics.

- Removable Terminals: Simplifies wiring and maintenance, allowing for pre-wiring or easy replacement without disturbing existing wire connections.

- Cost-Effective: Offers a robust safety solution for common applications without the complexity or cost of a full safety PLC.

Precautions

When working with the 440R-H231180 safety relay, it is crucial to observe these precautions:

- Safety First: This is a safety device. Never bypass or tamper with safety circuits. Proper installation and commissioning by qualified personnel are paramount to ensure its protective function.

- Power Disconnection: Always disconnect and lock out/tag out all power sources to the machine and control panel before installing, wiring, or servicing the safety relay or any associated safety components.

- Proper Wiring: Adhere strictly to the wiring diagrams provided in the product manual. Incorrect wiring can compromise the safety function and lead to hazardous situations. Pay close attention to dual-channel wiring for safety inputs.

- Component Compatibility: Ensure that all connected safety devices (E-stops, safety switches) are compatible with the relay’s input specifications and are rated for the required safety level.

- Testing: After installation and commissioning, thoroughly test the entire safety system to verify that it functions correctly and that all safety devices initiate a safe stop as intended. Regular functional testing should also be performed as per safety standards.

- Environmental Conditions: Install the relay in a clean, dry environment within its specified operating temperature range. Avoid excessive vibration or direct exposure to contaminants.

- Load Sizing: Ensure that the current and voltage ratings of the safety outputs are not exceeded by the devices they control (e.g., contactor coils). Use appropriately sized intermediate relays or contactors if necessary.

Product Applications

The Allen-Bradley 440R-H231180 safety relay is widely applied in various industrial machinery and systems where fundamental machine safety functions are required. Common applications include:

- Emergency Stop Circuits: Monitoring single or multiple E-Stop buttons across a machine or production line, ensuring immediate power removal in an emergency.

- Safety Gate Monitoring: Interlocking safety guards and doors, ensuring machinery cannot operate or safely stops when a guard is open.

- Light Curtain Integration: Integrating with safety light curtains or safety scanners to stop hazardous motion when personnel enter a protected area.

- Two-Hand Control Applications: Used in conjunction with two-hand control devices to ensure operators use both hands to initiate a hazardous cycle.

- Machine Enclosure Protection: Providing safety for access points to hazardous machinery.

- Conveyor System Safety: Ensuring conveyors stop when an E-Stop is pressed or a safety gate is opened.

- Robotics: Part of the safety circuit for robotic work cells to ensure safe interaction between humans and robots.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 1606-XLS480EC | Allen-Bradley | 2090-XXLF-TC3100 | Allen-Bradley |

| 191S-ANEJ3-CB25C | Allen-Bradley | 22B-B5P0C104 | Allen-Bradley |

| 2090-CFBM7E7-CDAF15 | Allen-Bradley | 280D-F12Z-NC-R | Allen-Bradley |

| 2090-CPWM7DF-16AF30 | Allen-Bradley | 418283-26A | Allen-Bradley |

| 2090-XXTPMP-10S12 | Allen-Bradley | 440F-M0436BYNN | Allen-Bradley |

| 25B-D6P0N114 | Allen-Bradley | 440F-M0624AYNN | Allen-Bradley |

| 440F-EEAKN01000 | Allen-Bradley | 440F-M0624BYNN | Allen-Bradley |

| 440F-EHARR00700 | Allen-Bradley | 440F-M0911DYNN | Allen-Bradley |

| 440F-M0606FYNN | Allen-Bradley | 440F-M0916BYNN | Allen-Bradley |

| 440T-MRKSE13AA | Allen-Bradley | 440F-M1212AYNN | Allen-Bradley |

| 440T-MRKSE13AB | Allen-Bradley | 440F-M1212BYNN | Allen-Bradley |

| 802C-TCB-100 | Allen-Bradley | 45MLA-AT0450P25 | Allen-Bradley |

| 847H-DL2A-AG00500 | Allen-Bradley | 700-R220A1 | Allen-Bradley |

| 847H-DN2A-RG01024 | Allen-Bradley | 800H-2HA7P | Allen-Bradley |

| 847H-DN2A-RH00600 | Allen-Bradley | 800H-2HB7P | Allen-Bradley |

| 9324-RLM0800ENM | Allen-Bradley | 800H-2HD7P | Allen-Bradley |

| 100-DCE-210 | Allen-Bradley | 800H-2HF7P | Allen-Bradley |

| 1336-FAN-SP1A | Allen-Bradley | 800H-2HG7P | Allen-Bradley |

| 2090-XXNPMF-16S20 | Allen-Bradley | SK-20P-S5D41 | Allen-Bradley |

| 25C-E1P7N104 | Allen-Bradley | 1485A-KCRIMP | Allen-Bradley |

| 440F-EEAMV01600 | Allen-Bradley | 191S-ANEJ3-CB16C | Allen-Bradley |

| 440F-EFFOV00650 | Allen-Bradley | 194R-B160-1753 | Allen-Bradley |

| 440F-M0425DYNN | Allen-Bradley | 194R-D160-1753 | Allen-Bradley |

| 440F-M0520DYNN | Allen-Bradley | 22B-B8P0F104 | Allen-Bradley |

| 440F-M1010DBNN | Allen-Bradley | 440F-EAFBV01219 | Allen-Bradley |

| 440F-M1010DYNN | Allen-Bradley | 440F-ECAOU01100 | Allen-Bradley |

| 440T-MRKSE130A | Allen-Bradley | 440F-ECAOV01120 | Allen-Bradley |

| 445L-R4S0240YD | Allen-Bradley | 440F-EEAFV01100 | Allen-Bradley |

| 9800-DC8ABDRIVB | Allen-Bradley | 440F-M0304CYNN | Allen-Bradley |

| SK-G9-XFMR2-F5 | Allen-Bradley | 440K-H04036 | Allen-Bradley |

| 440L-ALAT | Allen-Bradley | 440K-H04037 | Allen-Bradley |

| 440L-T4A2500YD | Allen-Bradley | 440K-H04038 | Allen-Bradley |

| 608881-103V | Allen-Bradley | 45CSA-103743-L1368 | Allen-Bradley |

| 800H-4HVX7 | Allen-Bradley | 80026-096-01-R | Allen-Bradley |

| H3M45048 | Allen-Bradley | 800H-2HAF4R | Allen-Bradley |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: