Description

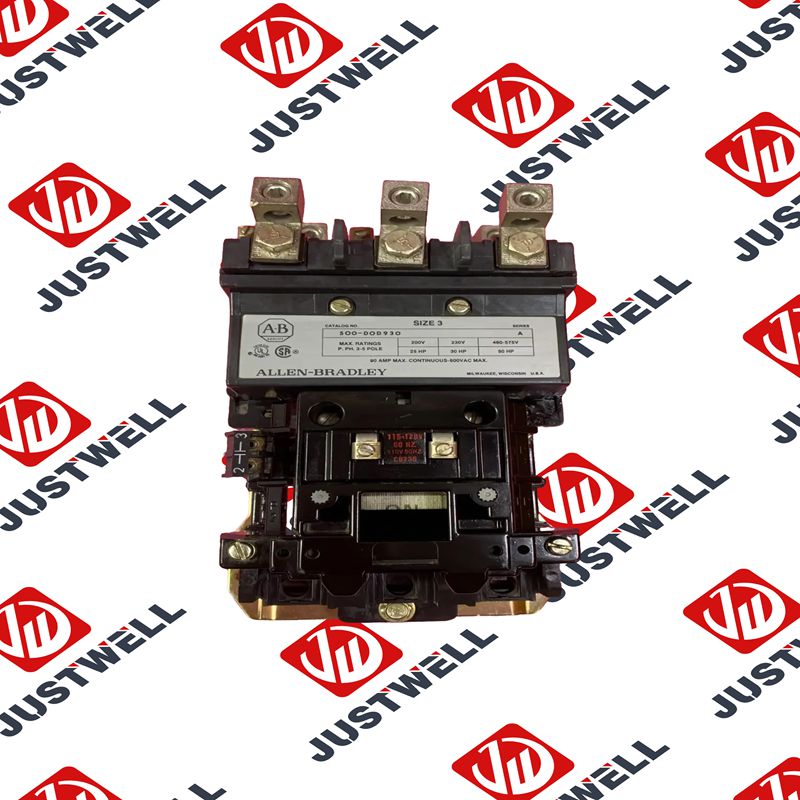

500-DOD930 Allen-Bradley contactor component module

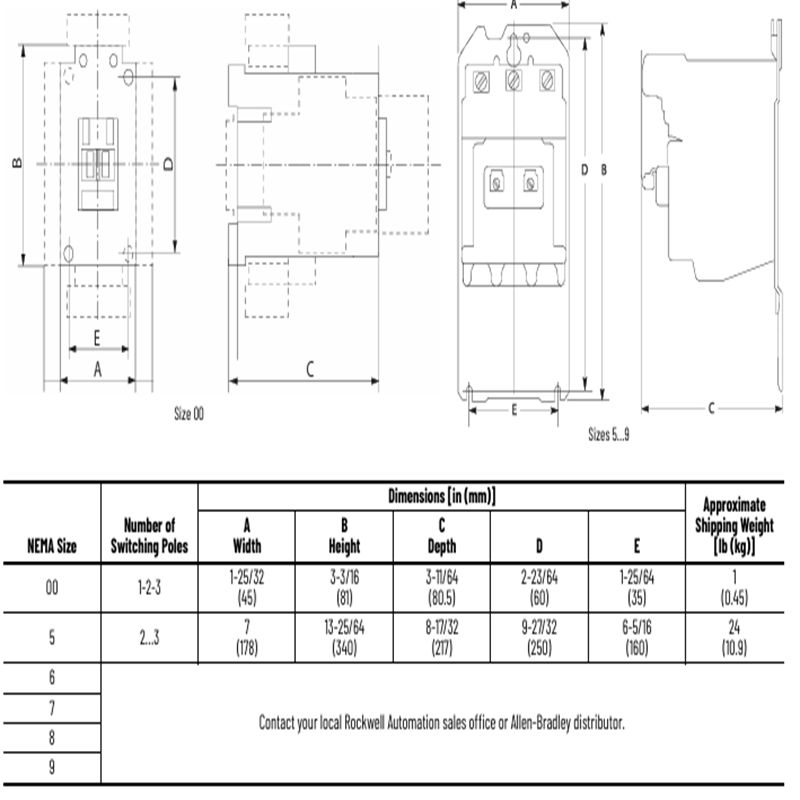

Product Dimensions:

Product Description

The 500-DOD930 is a NEMA-rated magnetic contactor, built for demanding industrial environments. Unlike IEC contactors which focus on space-saving and specific international standards, NEMA contactors prioritize ruggedness, longevity, and ease of maintenance in North American applications. This specific model is a 3-pole, non-reversing type, meaning it controls three phases of AC power and is designed for applications where the motor only needs to run in one direction. It includes an electromagnetic coil which, when energized, closes the main power contacts to supply power to the motor or load. The “DOD930” part of the catalog number indicates the specific NEMA size, configuration, and coil voltage, which in this case is 120V AC, 60Hz.

Product Parameters

Here are the key specifications for the Allen-Bradley 500-DOD930:

- Series: Bulletin 500 (NEMA Rated Contactor)

- Contactor Type: Non-Reversing

- Number of Poles: 3 (for 3-phase AC loads)

- NEMA Size: 3

- Rated Current (Continuous): 90 A (Amperes)

- Maximum Voltage: 600V AC

- Coil Voltage: 120V AC, 60 Hz

- Horsepower Ratings (Typical, NEMA Standard):

- 25 HP at 200V AC, 3-Phase

- 30 HP at 230V AC, 3-Phase

- 50 HP at 460V AC, 3-Phase

- 50 HP at 575V AC, 3-Phase

- Auxiliary Contacts: Typically comes with 1 Normally Open (N.O.) and 1 Normally Closed (N.C.) auxiliary contact as standard (though configurations can vary with specific ordering options). These are for control circuit use, not power switching.

- Mounting: Panel Mount (usually via screws)

- Standards/Certifications: UL Listed, CSA Certified, NEMA rated.

- Construction: Open type (requires enclosure for protection)

Product Advantages

The 500-DOD930 offers significant advantages, especially in heavy-duty industrial settings:

- Robustness and Durability: NEMA contactors are built to a higher standard of ruggedness than IEC counterparts, providing exceptional longevity and reliability in harsh industrial environments with frequent operations.

- High Current Capacity: With a NEMA Size 3 rating and 90A continuous current, it can handle substantial motor loads, suitable for demanding applications.

- Ease of Maintenance: NEMA contactors are designed for field repairability. Components like contacts and coils can often be replaced, extending the life of the unit and reducing total cost of ownership.

- Standardization: NEMA sizes are standardized across manufacturers, simplifying replacement and interchangeability.

- Reliable Performance: Known for their dependable operation, especially in applications with frequent starts and stops.

- Common Control Voltage: The 120V AC coil is a very common control voltage in North American industrial facilities, simplifying integration.

Precautions

When installing, operating, or maintaining the 500-DOD930 contactor, it is imperative to observe the following precautions:

- Electrical Hazard: Always de-energize and implement lockout/tagout procedures on all power sources to the motor, contactor, and control circuit before performing any installation, wiring, or maintenance. Failure to do so can result in severe injury or death.

- Proper Sizing: Ensure the contactor’s NEMA size, current, and voltage ratings are fully compatible with the specific motor or load it will control. Undersizing can lead to overheating and premature failure.

- Overload Protection: A contactor only switches power; it does not provide overload protection for the motor. It is absolutely essential to use an appropriately sized overload relay (e.g., Allen-Bradley Bulletin 592 or 595) in series with the contactor to protect the motor from damaging overcurrents.

- Enclosure: This contactor is typically an “open type” device. It must be installed within a suitable NEMA-rated enclosure to protect it from dust, moisture, and accidental contact, and to meet safety codes.

- Wiring Practices: Follow all applicable national and local electrical codes (e.g., NEC in the USA). Use properly sized copper conductors for the main power circuits and control circuits. Ensure all connections are tight to prevent loose contacts and overheating.

- Environmental Conditions: Install the contactor in an environment within its specified operating temperature range and protected from excessive vibration, corrosive atmospheres, and direct exposure to liquids.

- Auxiliary Contacts: Wire auxiliary contacts only for control circuit functions (e.g., pilot lights, interlocks, PLC inputs). Do not use them for switching main power loads.

- Coil Voltage: Verify that the supply voltage to the coil matches the 120V AC, 60Hz rating of the contactor to ensure proper operation and prevent coil damage.

Product Applications

The Allen-Bradley 500-DOD930 contactor is a foundational component in industrial electrical control, widely used for:

- Motor Starting (Direct-On-Line): The primary application is for starting and stopping medium to large 3-phase AC induction motors in “direct-on-line” (full voltage) starter configurations when combined with a thermal overload relay.

- Heavy-Duty Industrial Machinery: Powering and controlling motors for heavy equipment such as large compressors, pumps, fans, conveyors, crushers, and mixers.

- Heating Loads: Switching high-current industrial heating elements in ovens, furnaces, or process heaters.

- Power Distribution: Acting as a switching device for large electrical loads in industrial power distribution panels.

- Lighting Control: Controlling large banks of industrial or stadium lighting.

- Capacitor Switching: Used in power factor correction systems for switching large capacitor banks.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 1606-XLS480EC | Allen-Bradley | 2090-XXLF-TC3100 | Allen-Bradley |

| 191S-ANEJ3-CB25C | Allen-Bradley | 22B-B5P0C104 | Allen-Bradley |

| 2090-CFBM7E7-CDAF15 | Allen-Bradley | 280D-F12Z-NC-R | Allen-Bradley |

| 2090-CPWM7DF-16AF30 | Allen-Bradley | 418283-26A | Allen-Bradley |

| 2090-XXTPMP-10S12 | Allen-Bradley | 440F-M0436BYNN | Allen-Bradley |

| 25B-D6P0N114 | Allen-Bradley | 440F-M0624AYNN | Allen-Bradley |

| 440F-EEAKN01000 | Allen-Bradley | 440F-M0624BYNN | Allen-Bradley |

| 440F-EHARR00700 | Allen-Bradley | 440F-M0911DYNN | Allen-Bradley |

| 440F-M0606FYNN | Allen-Bradley | 440F-M0916BYNN | Allen-Bradley |

| 440T-MRKSE13AA | Allen-Bradley | 440F-M1212AYNN | Allen-Bradley |

| 440T-MRKSE13AB | Allen-Bradley | 440F-M1212BYNN | Allen-Bradley |

| 802C-TCB-100 | Allen-Bradley | 45MLA-AT0450P25 | Allen-Bradley |

| 847H-DL2A-AG00500 | Allen-Bradley | 700-R220A1 | Allen-Bradley |

| 847H-DN2A-RG01024 | Allen-Bradley | 800H-2HA7P | Allen-Bradley |

| 847H-DN2A-RH00600 | Allen-Bradley | 800H-2HB7P | Allen-Bradley |

| 9324-RLM0800ENM | Allen-Bradley | 800H-2HD7P | Allen-Bradley |

| 100-DCE-210 | Allen-Bradley | 800H-2HF7P | Allen-Bradley |

| 1336-FAN-SP1A | Allen-Bradley | 800H-2HG7P | Allen-Bradley |

| 2090-XXNPMF-16S20 | Allen-Bradley | SK-20P-S5D41 | Allen-Bradley |

| 25C-E1P7N104 | Allen-Bradley | 1485A-KCRIMP | Allen-Bradley |

| 440F-EEAMV01600 | Allen-Bradley | 191S-ANEJ3-CB16C | Allen-Bradley |

| 440F-EFFOV00650 | Allen-Bradley | 194R-B160-1753 | Allen-Bradley |

| 440F-M0425DYNN | Allen-Bradley | 194R-D160-1753 | Allen-Bradley |

| 440F-M0520DYNN | Allen-Bradley | 22B-B8P0F104 | Allen-Bradley |

| 440F-M1010DBNN | Allen-Bradley | 440F-EAFBV01219 | Allen-Bradley |

| 440F-M1010DYNN | Allen-Bradley | 440F-ECAOU01100 | Allen-Bradley |

| 440T-MRKSE130A | Allen-Bradley | 440F-ECAOV01120 | Allen-Bradley |

| 445L-R4S0240YD | Allen-Bradley | 440F-EEAFV01100 | Allen-Bradley |

| 9800-DC8ABDRIVB | Allen-Bradley | 440F-M0304CYNN | Allen-Bradley |

| SK-G9-XFMR2-F5 | Allen-Bradley | 440K-H04036 | Allen-Bradley |

| 440L-ALAT | Allen-Bradley | 440K-H04037 | Allen-Bradley |

| 440L-T4A2500YD | Allen-Bradley | 440K-H04038 | Allen-Bradley |

| 608881-103V | Allen-Bradley | 45CSA-103743-L1368 | Allen-Bradley |

| 800H-4HVX7 | Allen-Bradley | 80026-096-01-R | Allen-Bradley |

| H3M45048 | Allen-Bradley | 800H-2HAF4R | Allen-Bradley |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: