Description

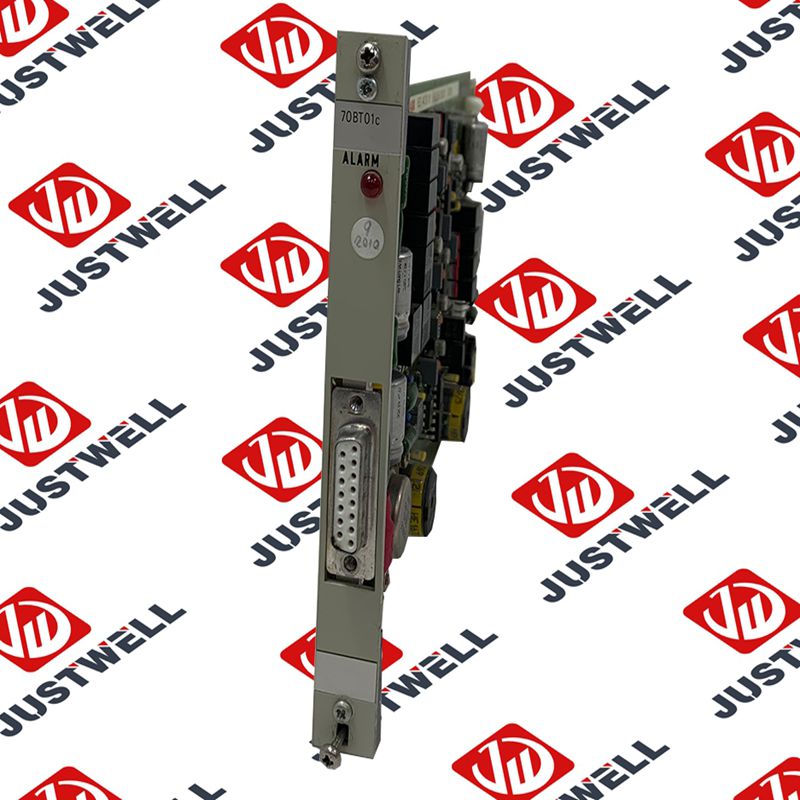

6DD1660-0BD0 SIEMENS Simulation output module

Product Dimensions:

Product Description

A SIEMENS Simulation Output Module (or a standard I/O module utilized for simulation purposes) is designed to facilitate the testing and commissioning of an automation system without requiring physical connection to actual field actuators.

In essence, these modules allow engineers to manually override or force the output status from the physical component, simulating the action of an actuator (e.g., a motor turning on, a valve opening, or a heater engaging). This capability is crucial during the development phase to verify the control logic (PLC program) and sequence behavior. Simulation features are typically achieved either through dedicated modules with manual switches/buttons or, more commonly, through integrated software functions (forcing) within the engineering environment (e.g., TIA Portal) that bypass the logic’s calculated output value.

Product Parameters

Parameters related to simulation functionality focus on ease of use and interface:

- Control Mechanism: Toggle switches, push buttons, or rotary encoders on the module face for manual control (if a dedicated hardware module).

- Signal Status Indication: LEDs corresponding to each channel to show the current simulated output status (ON/OFF or a scaled analog value).

- Channel Density: Typically matches standard I/O modules (e.g., 8 or 16 channels for digital simulation).

- Integration: Seamless integration with the central controller and engineering software (e.g., forcing functions accessible in the TIA Portal Watch Tables).

- Power: Draws power from the backplane or a dedicated simulation power supply.

- Safety Lockout: Often includes a mechanism to physically or logically prevent simultaneous simulation and run-time operation to avoid unintended behavior.

Product Advantages

- Accelerated Commissioning: Allows the control program to be thoroughly tested and debugged before the actual field wiring and actuator installation are complete, significantly reducing startup time.

- Non-Invasive Testing: Enables the testing of critical control sequences (e.g., interlocks, emergency stops) without risking damage to expensive or sensitive mechanical equipment.

- Systematic Debugging: Provides a clear, manual interface to systematically check the response of the PLC logic to various output conditions.

- Training and Troubleshooting: Excellent tools for operator training and for quickly diagnosing field issues by isolating whether a fault lies in the control logic or the field device.

- Safe Operation: Dedicated hardware simulation modules often include a safe operational mode (e.g., keyswitch-enabled) ensuring that simulation cannot accidentally interfere with live production.

Important Notes

- Avoid Live Use: Simulation functions (especially software “forcing”) must not be used on I/O modules connected to live processes or equipment in a production environment, as this can override safety logic and lead to dangerous situations.

- Return to Normal: After commissioning or testing, the system must be rigorously checked to ensure all simulation features and software “forces” have been completely deactivated and removed.

- Documentation: All uses of simulation or forcing functions during commissioning must be properly logged and documented to track changes to the system behavior.

- Signal Type Specificity: Ensure the simulation tool or module is appropriate for the signal type being tested (digital simulation for digital I/O, analog simulation for analog I/O).

Product Applications

Simulation Output modules are invaluable across all phases of the automation project lifecycle, primarily in non-production environments:

- Software Testing (FAT/SAT): Essential for Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) to demonstrate control logic functionality to the client.

- Virtual Commissioning: Used in conjunction with digital twin technology to fully simulate the plant environment and validate complex control sequences.

- Program Debugging: Allowing engineers to step through the program and verify that the PLC logic is correctly calculating and driving the intended output values.

- Operator and Maintenance Training: Used to simulate various fault conditions and operational scenarios in a safe environment for training purposes.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 6GK5206-1BC10-2AA3 | SIEMENS | 6SE6400-0AP00-0AA1 | SIEMENS |

| 6ES7193-0CB20-0XA0 | SIEMENS | 6XV1840-3AH10 60m | SIEMENS |

| 6ES7323-1BH01-0AA0 | SIEMENS | QMX2.P33 | SIEMENS |

| 16137-175 | SIEMENS | PXC100-E96A | SIEMENS |

| 6GK443-1EX30-0XE1 | SIEMENS | 5SX2102-7 | SIEMENS |

| 6EP3331-6SB00-0AY0 | SIEMENS | 3ZX1012-ORTO2-1AA1 | SIEMENS |

| PXC50-E.D | SIEMENS | 6ES7151-1BA02-0AB0 | SIEMENS |

| 6AV2124-0QC24-1AX0 | SIEMENS | 6FX2001-6AA12-2AA5- 1 | SIEMENS |

| 6SL31201TE285AA3 | SIEMENS | 6ES7195-7HB00-0XA0 | SIEMENS |

| 6SL31622BM000AA0 | SIEMENS | 6SL34202TE150AA1 | SIEMENS |

| 6SE7972-0CB20-0XA0 | SIEMENS | 6SL3053-0AA00-3AA1 | SIEMENS |

| 3RX9307-1AA00 | SIEMENS | 6AV2124-0JC01-0AX0-ZA01+S00 | SIEMENS |

| 3RK1903-3AC00 | SIEMENS | QRA75.A17 | SIEMENS |

| 6GK5992-1AG00-8AA0 | SIEMENS | 3RT1054-1AT36 | SIEMENS |

| 6GK5980-3CB00-0AA1 | SIEMENS | 7MF4033-1DA10-1AC6-Z | SIEMENS |

| 6AG4141-0BA34-0EA0 | SIEMENS | 6AV8100-1CB00-0AA1 | SIEMENS |

| 5SU1324-7FA06 | SIEMENS | 3VL1705-1DA33-0AB1 | SIEMENS |

| 6SE7011-5EP50-Z | SIEMENS | 6SA8252-0BC83 | SIEMENS |

| 6DR2803-8P | SIEMENS | 6SN1124-1AB00-0HA1 | SIEMENS |

| FK-6DR4004-8J | SIEMENS | AK1703ACP | SIEMENS |

| 6SL3210 -1SE31-0UA0 | SIEMENS | 6SL3225-0BH27-5AA1 | SIEMENS |

| 6AV6645-0DE01-0AX1 | SIEMENS | 3TY7530-0A | SIEMENS |

| 6XV1870-8AN30 | SIEMENS | 3UG4512-1AR20 | SIEMENS |

| 3SE5132-0CJ82 | SIEMENS | 7SJ8021-5EB90-1FA0/DD | SIEMENS |

| 3RT1046-1BB44 + 3RH1921-1HA22 | SIEMENS | 3RH2911-1HA02 | SIEMENS |

| 3TF4522-0XM0 | SIEMENS | 6ES7288-1CR40-0AA0 | SIEMENS |

| 6AV2128-3UB06-0AX1 | SIEMENS | 6SE7090-0XX84-3EH0 | SIEMENS |

| 6SL3220-3YE30-0UF0 | SIEMENS | 6ES7135-0HF01-0XB0 | SIEMENS |

| 6SL3220-1YE34-0UF0 | SIEMENS | 6AG1134-4GB01-2AB0 | SIEMENS |

| TXM1.4D3R | SIEMENS | 6SC6508-4AA02 | SIEMENS |

| TXM1.6R | SIEMENS | 6SL3130-7TE25-5AA3 | SIEMENS |

| PXC4.E16 | SIEMENS | 8PQ9142-2AA04 | SIEMENS |

| QBM3120 | SIEMENS | 6ES7-214-1BD23-0XB8 | SIEMENS |

| TXS1-EF10 | SIEMENS | PXG80-N | SIEMENS |

| 6AG1231-4HD32-4XB0 | SIEMENS | 6GK51011BB002AA3 | SIEMENS |

| QVE1901 | SIEMENS | 6AG1137-6AA00-2BA0 | SIEMENS |

| QPA1004 | SIEMENS | 6EP1334-1AL11 | SIEMENS |

| GLB161.1E | SIEMENS | 6FX8002-2DC10-1EA0 | SIEMENS |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: