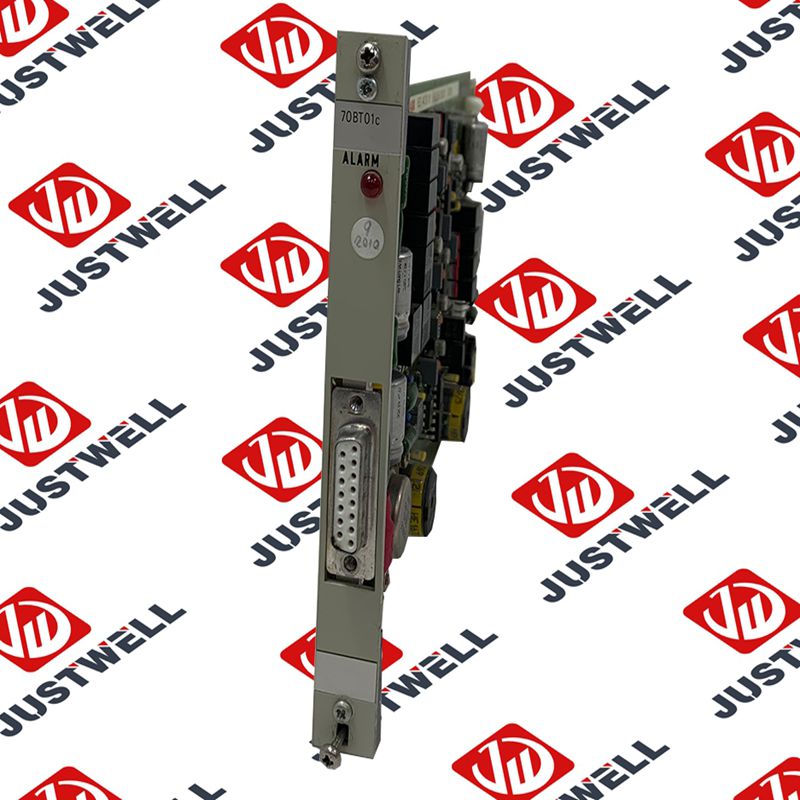

Description

6SL3225-0BE32-2UA0 SIEMENS I/O module

Product Dimensions:

Product Description

A Siemens I/O Module is a fundamental, modular component within the Siemens automation system (such as a PLC or Distributed I/O system). These modules serve as the physical interface between the central Processor Module and the real-world field devices, acting as the sensing and actuating layer of the control system.

I/O modules can be broadly categorized as:

-

Digital I/O: Handling binary (ON/OFF) signals from switches, pushbuttons, solenoids, and indicators.

-

Analog I/O: Handling continuous signals (voltage, current, temperature) from transmitters, sensors, and proportional valves.

-

Special Function I/O: Modules dedicated to complex tasks like high-speed counting, position sensing, or specialized communications.

The I/O module’s role is to convert field signals into internal digital data for the CPU (inputs) and convert CPU commands into external electrical signals for actuators (outputs).

Product Parameters

The specifications for I/O modules encompass the capability of both input and output channels:

| Parameter | Description |

| Channel Count | The number of connection points on the module (e.g., 8, 16, 32 channels per module). |

| Signal Type/Level | The acceptable electrical characteristics, such as 24V DC, 120V AC, $4text{-}20text{mA}$ current, or $0text{-}10text{V}$ voltage. |

| Output Load Rating | The maximum current (Amps) that a digital output channel can switch, and the voltage/current range for analog outputs. |

| Resolution (Analog) | The precision of Analog I/O conversion, typically measured in bits (e.g., 14-bit or 16-bit). |

| Data Update Rate | How quickly the module can process and transmit input data to, or receive output data from, the CPU (often in $text{ms}$). |

| Galvanic Isolation | The electrical separation between channels, channel groups, and the backplane to prevent electrical interference and damage. |

| Connection Method | The physical wiring method supported, such as screw terminals, push-in terminals, or system cabling via a front connector. |

Product Advantages

-

Flexibility and Customization: The modular nature allows users to combine a wide variety of I/O types (digital, analog, temperature, safety) on a single system to precisely meet the application’s needs.

-

Integrated Diagnostics: Advanced modules offer channel-level diagnostics, automatically detecting and reporting issues like wire breaks, short circuits, and out-of-range analog values directly to the engineering software.

-

High Reliability: Built to stringent industrial standards, these modules ensure reliable data acquisition and control command execution in electrically noisy and thermally challenging environments.

-

Hot Swapping Capability: In many systems, I/O modules can be replaced while the system remains powered on (hot swap), significantly reducing machine downtime during maintenance.

-

Standardized Interfacing: Uses standardized front connectors and mounting rails, ensuring quick, error-free installation and easy replacement.

Important Precautions

-

Wiring Integrity: Ensure all wiring terminations are secure and correctly seated in the terminals to prevent intermittent faults, particularly with high-vibration applications.

-

Load Protection: Always check that the external current protection (fuses) for output circuits is appropriately sized for the load and the module’s rating.

-

System Power Budget: When adding modules, verify that the total current draw for the backplane and power rail does not exceed the capacity of the system’s Power Supply Module.

-

Grounding and Shielding: Implement proper grounding schemes and use shielded cables for analog signals and high-speed communication to maintain signal quality and reduce common-mode interference.

-

Address Consistency: Ensure that the configured I/O addresses in the control program exactly match the physical slot positions of the modules in the rack or bus.

Product Applications

I/O modules are universally applied wherever industrial processes are automated:

-

Manufacturing Assembly Lines: Interfacing with pneumatic cylinders, robotic end-effectors, and part sensors.

-

Utility Monitoring: Reading signals from flow meters and pressure sensors in water treatment and distribution networks.

-

Machine Control: Providing feedback loops for temperature control, using analog inputs from thermocouples and analog outputs to heaters.

-

Remote Control: Extending the reach of the central controller by placing I/O modules closer to field devices using distributed I/O networks.

-

Safety Applications: Utilizing specialized I/O modules to monitor safety-critical devices and execute safe shutdowns according to safety standards.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 6GK5206-1BC10-2AA3 | SIEMENS | 6SE6400-0AP00-0AA1 | SIEMENS |

| 6ES7193-0CB20-0XA0 | SIEMENS | 6XV1840-3AH10 60m | SIEMENS |

| 6ES7323-1BH01-0AA0 | SIEMENS | QMX2.P33 | SIEMENS |

| 16137-175 | SIEMENS | PXC100-E96A | SIEMENS |

| 6GK443-1EX30-0XE1 | SIEMENS | 5SX2102-7 | SIEMENS |

| 6EP3331-6SB00-0AY0 | SIEMENS | 3ZX1012-ORTO2-1AA1 | SIEMENS |

| PXC50-E.D | SIEMENS | 6ES7151-1BA02-0AB0 | SIEMENS |

| 6AV2124-0QC24-1AX0 | SIEMENS | 6FX2001-6AA12-2AA5- 1 | SIEMENS |

| 6SL31201TE285AA3 | SIEMENS | 6ES7195-7HB00-0XA0 | SIEMENS |

| 6SL31622BM000AA0 | SIEMENS | 6SL34202TE150AA1 | SIEMENS |

| 6SE7972-0CB20-0XA0 | SIEMENS | 6SL3053-0AA00-3AA1 | SIEMENS |

| 3RX9307-1AA00 | SIEMENS | 6AV2124-0JC01-0AX0-ZA01+S00 | SIEMENS |

| 3RK1903-3AC00 | SIEMENS | QRA75.A17 | SIEMENS |

| 6GK5992-1AG00-8AA0 | SIEMENS | 3RT1054-1AT36 | SIEMENS |

| 6GK5980-3CB00-0AA1 | SIEMENS | 7MF4033-1DA10-1AC6-Z | SIEMENS |

| 6AG4141-0BA34-0EA0 | SIEMENS | 6AV8100-1CB00-0AA1 | SIEMENS |

| 5SU1324-7FA06 | SIEMENS | 3VL1705-1DA33-0AB1 | SIEMENS |

| 6SE7011-5EP50-Z | SIEMENS | 6SA8252-0BC83 | SIEMENS |

| 6DR2803-8P | SIEMENS | 6SN1124-1AB00-0HA1 | SIEMENS |

| FK-6DR4004-8J | SIEMENS | AK1703ACP | SIEMENS |

| 6SL3210 -1SE31-0UA0 | SIEMENS | 6SL3225-0BH27-5AA1 | SIEMENS |

| 6AV6645-0DE01-0AX1 | SIEMENS | 3TY7530-0A | SIEMENS |

| 6XV1870-8AN30 | SIEMENS | 3UG4512-1AR20 | SIEMENS |

| 3SE5132-0CJ82 | SIEMENS | 7SJ8021-5EB90-1FA0/DD | SIEMENS |

| 3RT1046-1BB44 + 3RH1921-1HA22 | SIEMENS | 3RH2911-1HA02 | SIEMENS |

| 3TF4522-0XM0 | SIEMENS | 6ES7288-1CR40-0AA0 | SIEMENS |

| 6AV2128-3UB06-0AX1 | SIEMENS | 6SE7090-0XX84-3EH0 | SIEMENS |

| 6SL3220-3YE30-0UF0 | SIEMENS | 6ES7135-0HF01-0XB0 | SIEMENS |

| 6SL3220-1YE34-0UF0 | SIEMENS | 6AG1134-4GB01-2AB0 | SIEMENS |

| TXM1.4D3R | SIEMENS | 6SC6508-4AA02 | SIEMENS |

| TXM1.6R | SIEMENS | 6SL3130-7TE25-5AA3 | SIEMENS |

| PXC4.E16 | SIEMENS | 8PQ9142-2AA04 | SIEMENS |

| QBM3120 | SIEMENS | 6ES7-214-1BD23-0XB8 | SIEMENS |

| TXS1-EF10 | SIEMENS | PXG80-N | SIEMENS |

| 6AG1231-4HD32-4XB0 | SIEMENS | 6GK51011BB002AA3 | SIEMENS |

| QVE1901 | SIEMENS | 6AG1137-6AA00-2BA0 | SIEMENS |

| QPA1004 | SIEMENS | 6EP1334-1AL11 | SIEMENS |

| GLB161.1E | SIEMENS | 6FX8002-2DC10-1EA0 | SIEMENS |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: