Description

700-FSM3UU23-EX Allen-Bradley Safety Control Relay

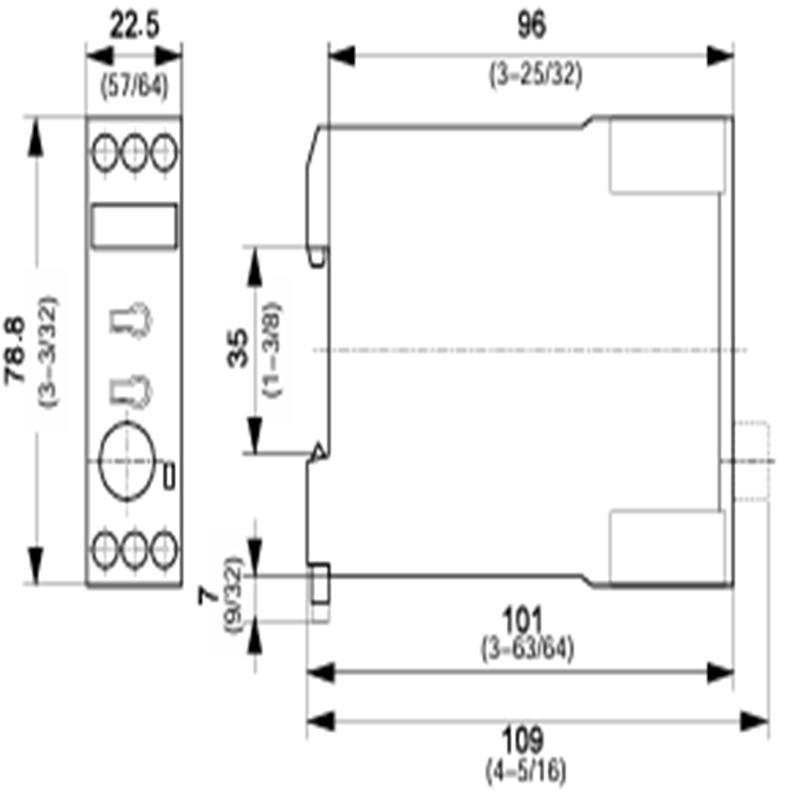

Product Dimensions:

Product Description

The Allen-Bradley Guardmaster 700-FSM3UU23-EX is a multi-function safety relay from the Minotaur MSR210P series, specifically designed for use in hazardous (Ex) locations. This relay is highly versatile, capable of monitoring various safety devices such as E-stop buttons, safety gates, light curtains, and pressure mats. Its key feature is the ability to operate safely and reliably in environments where flammable gases, vapors, mists, or combustible dusts may be present. The “3UU23” in the catalog number typically indicates specific input/output configurations and power supply.

Product Parameters

Here are the key specifications for the 700-FSM3UU23-EX:

- Catalog Number: 700-FSM3UU23-EX

- Series: Guardmaster Minotaur MSR210P series (often part of the 440R family)

- Function: Multi-function Safety Relay

- Inputs:

- Universal Inputs: Capable of monitoring E-stops, safety gates (single or dual channel), light curtains, and pressure mats.

- Input Configuration: Can typically be configured for 1-channel or 2-channel inputs, with or without cross-fault monitoring.

- Outputs:

- Safety Outputs: Typically 3 Normally Open (NO) safety outputs, designed to switch the power to the machine’s final control elements (e.g., contactors).

- Auxiliary Output: Usually 1 Normally Closed (NC) auxiliary output for status indication or non-safety related functions.

- Power Supply: 24V AC/DC (confirm exact voltage from datasheet, as some models may vary).

- Reset Type: Configurable for Automatic/Manual or Monitored Manual Reset.

- Terminal Type: Removable screw terminals.

- Mounting: DIN Rail mountable.

- Hazardous Location Rating: EX-rated (e.g., ATEX, IECEx certified for specific zones/classes). It’s crucial to check the specific hazardous area classification (e.g., Zone 2, Zone 22, Class I Div 2) on the product’s official datasheet and certification for proper application.

- Ingress Protection (IP) Rating: IP20 (terminal protection), generally intended for installation within an appropriate EX-rated enclosure.

- Safety Category/Performance Level: Designed to achieve high safety integrity levels (e.g., up to PLe / Category 4 per EN ISO 13849-1, SIL 3 per IEC 61508) when correctly integrated into a safety system.

- Operating Temperature: Typically -5 °C to +55 °C (+23 °F to +131 °F).

- Dimensions (Approximate): Compact, typically 45mm width for DIN rail mounting.

Product Advantages

- Hazardous Location Certified: The primary advantage is its EX certification, making it suitable for safety applications in potentially explosive atmospheres where standard relays cannot be used.

- Multi-Functionality: Versatile enough to monitor various types of safety devices, reducing the need for multiple single-purpose relays.

- High Safety Integrity: Designed to achieve high Performance Levels (PLe) and Safety Integrity Levels (SIL), ensuring robust safety in critical applications.

- Diagnostic Capabilities: Provides clear status indication via LEDs, aiding in troubleshooting and reducing downtime.

- Flexible Configuration: Offers configurable reset modes and input channels to adapt to diverse application requirements.

- Compact Design: Saves valuable panel space due to its slim profile.

- Ease of Wiring: Removable screw terminals simplify installation and maintenance.

- Reliability: As an Allen-Bradley Guardmaster product, it offers high reliability and long operational life, minimizing unexpected failures.

Precautions

- EX Certification Verification: Absolutely critical: Always verify the specific EX certification details (gas/dust groups, temperature classes, zones/divisions) on the actual product label and official documentation to ensure it matches the hazardous area classification of your installation. Misapplication in an uncertified zone can be extremely dangerous.

- Proper Enclosure: The relay itself is IP20. For hazardous locations, it must be installed within an appropriately certified and rated Ex enclosure that maintains the integrity of the hazardous area protection concept (e.g., explosion-proof, intrinsically safe, purged, or increased safety enclosure).

- Intrinsically Safe Circuits: If monitoring intrinsically safe field devices, ensure that any associated apparatus (e.g., barriers) are correctly selected and installed, and that the entire loop maintains intrinsic safety. The relay may have specific requirements for input connection in EX areas.

- Wiring Practices: Adhere strictly to hazardous area wiring practices (e.g., segregation of intrinsically safe and non-intrinsically safe wiring, correct cable glands).

- System Design and Validation: This is a component of a safety system. The entire safety circuit must be designed, installed, and validated by qualified personnel in accordance with relevant international and local safety standards (e.g., IEC 61508, EN ISO 13849-1, IEC 60079 series for EX).

- Power Supply: Ensure the power supply for the relay meets the specified voltage and is stable.

- Maintenance: Regularly inspect the relay and its connections. Do not open the relay in a hazardous atmosphere unless permitted by specific procedures and hot work permits.

Product Applications

The Allen-Bradley Guardmaster 700-FSM3UU23-EX safety relay is specifically used in industries and applications where safety functions are required in potentially explosive atmospheres. These include:

- Oil & Gas Industry: On drilling rigs, refineries, petrochemical plants, for emergency stops, safety gates on pumps, compressors, or processing equipment.

- Chemical Manufacturing: In areas where flammable chemicals are processed, for guarding mixers, reactors, and conveying systems.

- Pharmaceutical Production: In facilities handling flammable solvents or dusts, for securing access to process machinery.

- Grain Processing / Food & Beverage: In areas with combustible dust (e.g., flour, sugar, starch), for safeguarding conveyors, silos, and processing equipment.

- Paint and Coating Plants: Where flammable solvents are used, for safety interlocks on mixing tanks, spray booths, and ventilation systems.

- Mining Operations: In areas with methane gas or combustible dusts, for safety on conveyors, crushers, and material handling equipment.

- Any industrial process where personnel protection is required in a classified hazardous location.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 1606-XLS480EC | Allen-Bradley | 2090-XXLF-TC3100 | Allen-Bradley |

| 191S-ANEJ3-CB25C | Allen-Bradley | 22B-B5P0C104 | Allen-Bradley |

| 2090-CFBM7E7-CDAF15 | Allen-Bradley | 280D-F12Z-NC-R | Allen-Bradley |

| 2090-CPWM7DF-16AF30 | Allen-Bradley | 418283-26A | Allen-Bradley |

| 2090-XXTPMP-10S12 | Allen-Bradley | 440F-M0436BYNN | Allen-Bradley |

| 25B-D6P0N114 | Allen-Bradley | 440F-M0624AYNN | Allen-Bradley |

| 440F-EEAKN01000 | Allen-Bradley | 440F-M0624BYNN | Allen-Bradley |

| 440F-EHARR00700 | Allen-Bradley | 440F-M0911DYNN | Allen-Bradley |

| 440F-M0606FYNN | Allen-Bradley | 440F-M0916BYNN | Allen-Bradley |

| 440T-MRKSE13AA | Allen-Bradley | 440F-M1212AYNN | Allen-Bradley |

| 440T-MRKSE13AB | Allen-Bradley | 440F-M1212BYNN | Allen-Bradley |

| 802C-TCB-100 | Allen-Bradley | 45MLA-AT0450P25 | Allen-Bradley |

| 847H-DL2A-AG00500 | Allen-Bradley | 700-R220A1 | Allen-Bradley |

| 847H-DN2A-RG01024 | Allen-Bradley | 800H-2HA7P | Allen-Bradley |

| 847H-DN2A-RH00600 | Allen-Bradley | 800H-2HB7P | Allen-Bradley |

| 9324-RLM0800ENM | Allen-Bradley | 800H-2HD7P | Allen-Bradley |

| 100-DCE-210 | Allen-Bradley | 800H-2HF7P | Allen-Bradley |

| 1336-FAN-SP1A | Allen-Bradley | 800H-2HG7P | Allen-Bradley |

| 2090-XXNPMF-16S20 | Allen-Bradley | SK-20P-S5D41 | Allen-Bradley |

| 25C-E1P7N104 | Allen-Bradley | 1485A-KCRIMP | Allen-Bradley |

| 440F-EEAMV01600 | Allen-Bradley | 191S-ANEJ3-CB16C | Allen-Bradley |

| 440F-EFFOV00650 | Allen-Bradley | 194R-B160-1753 | Allen-Bradley |

| 440F-M0425DYNN | Allen-Bradley | 194R-D160-1753 | Allen-Bradley |

| 440F-M0520DYNN | Allen-Bradley | 22B-B8P0F104 | Allen-Bradley |

| 440F-M1010DBNN | Allen-Bradley | 440F-EAFBV01219 | Allen-Bradley |

| 440F-M1010DYNN | Allen-Bradley | 440F-ECAOU01100 | Allen-Bradley |

| 440T-MRKSE130A | Allen-Bradley | 440F-ECAOV01120 | Allen-Bradley |

| 445L-R4S0240YD | Allen-Bradley | 440F-EEAFV01100 | Allen-Bradley |

| 9800-DC8ABDRIVB | Allen-Bradley | 440F-M0304CYNN | Allen-Bradley |

| SK-G9-XFMR2-F5 | Allen-Bradley | 440K-H04036 | Allen-Bradley |

| 440L-ALAT | Allen-Bradley | 440K-H04037 | Allen-Bradley |

| 440L-T4A2500YD | Allen-Bradley | 440K-H04038 | Allen-Bradley |

| 608881-103V | Allen-Bradley | 45CSA-103743-L1368 | Allen-Bradley |

| 800H-4HVX7 | Allen-Bradley | 80026-096-01-R | Allen-Bradley |

| H3M45048 | Allen-Bradley | 800H-2HAF4R | Allen-Bradley |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: