Description

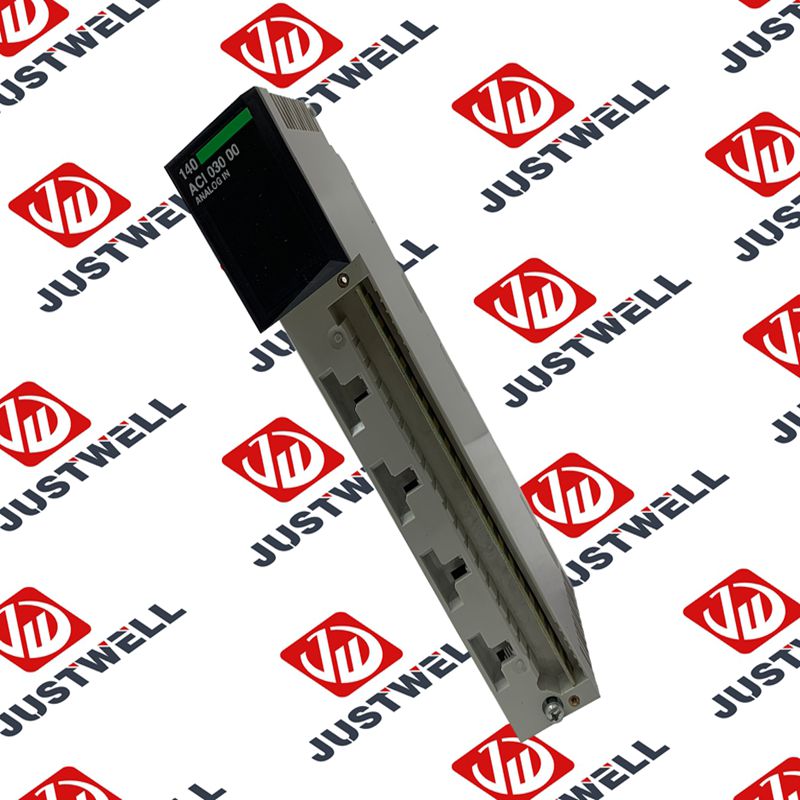

IC695ALG626-HC General Electric Input module

Product Dimensions:

Product Description

GE Input Modules are a fundamental component of a Programmable Logic Controller (PLC) or Distributed Control System (DCS). They act as the “senses” of the control system, serving as the crucial interface between the industrial equipment on the plant floor and the central processor. Their primary function is to receive electrical signals from various field devices—such as sensors, limit switches, pushbuttons, and thermocouples—and convert these signals into digital data that the processor can understand and process. These modules are specifically designed to be robust and reliable, capable of withstanding the harsh conditions of industrial environments, including electrical noise, temperature variations, and vibration. They are essential for monitoring the status of a process and for collecting real-time data to enable the control system to make informed decisions.

Product Specifications

The specifications of GE Input Modules are diverse and depend on the type of signal they are designed to handle. Key parameters include:

- Signal Type: The type of electrical signal the module can accept. This can be digital (discrete on/off signals) or analog (a continuous range of voltage or current, e.g., 0-10V, 4-20mA).

- Number of Channels: The number of independent input points on a single module. This can range from a few to dozens, depending on the module series.

- Voltage and Current Ratings: The electrical characteristics the module can handle, such as 24VDC, 120VAC, 4-20mA, or 0-10V. It’s critical to match the module’s ratings to the field device’s signal.

- Isolation: The level of electrical isolation between the input channels and the internal backplane. This protects the control system from voltage spikes and ground loops from the field devices.

- Response Time: The speed at which the module can detect and report a change in the input signal. A faster response time is essential for high-speed applications.

- Special Features: Some modules offer advanced features like high-speed counting, thermocouple/RTD inputs (for temperature measurement), or built-in diagnostics for open-wire detection.

- Sinking/Sourcing: For DC digital modules, this defines whether the module provides a path to ground (sinking) or a path to power (sourcing) for the input signal.

Product Advantages

GE Input Modules offer several significant benefits for industrial automation systems:

- Modularity and Scalability: The modular design allows you to easily expand the system’s monitoring capabilities by simply adding more input modules, without having to replace the entire control system.

- High Reliability: Engineered with rugged, industrial-grade components, these modules are designed for long-term, continuous operation in harsh environments, which minimizes system downtime and maintenance costs.

- Simplified Troubleshooting: Many modules feature built-in diagnostics with LED indicators that provide a quick visual status of each channel. This simplifies the identification of faulty sensors or broken wires.

- Versatility: With a wide array of module types (digital, analog, temperature, etc.), they can interface with nearly any type of industrial sensor, providing a flexible and universal solution for data acquisition.

- Protection and Safety: Electrical isolation and surge protection features safeguard the sensitive electronics of the control system from electrical disturbances originating in the field.

Product Applications

GE Input Modules are a core part of automated systems in a wide variety of industries, including:

- Manufacturing & Automation: Used to monitor the state of proximity sensors, limit switches, pressure sensors, and pushbuttons on a factory floor.

- Process Control: In chemical plants and refineries, they monitor temperature, pressure, and flow rates to ensure the process is operating within safe parameters.

- Power Generation: They monitor critical parameters such as temperature, vibration, and pressure in turbines, generators, and auxiliary systems.

- Water & Wastewater Treatment: They are used to monitor water levels, flow rates, and pH levels to ensure the treatment process is effective.

- Building Automation: They monitor sensors for temperature, humidity, light levels, and security systems within commercial and industrial buildings.

Precautions

To ensure the safe and reliable operation of GE Input Modules, follow these precautions:

- Proper Wiring: Use the correct wire gauges and follow the manufacturer’s wiring diagrams meticulously. Incorrect wiring can lead to module damage or inaccurate readings.

- Voltage Compatibility: Always ensure the voltage of the field device matches the specified voltage rating of the input module. Applying a higher voltage can permanently damage the module.

- Grounding: Proper grounding of the entire control system is crucial to prevent electrical noise and surges from affecting the input signals and to ensure the safety of the equipment and personnel.

- Environmental Conditions: Install the modules in a clean, dry, and temperature-controlled enclosure. Operating outside of the specified temperature and humidity ranges can lead to premature failure.

- ESD Protection: Handle the modules with care, especially during installation, to prevent damage from electrostatic discharge (ESD), which can destroy sensitive electronic components.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| IC660BBA025 | General Electric | 469-P5-HI-A20-T-H | General Electric |

| CR104PSG92B11 | General Electric | Multilin PQMII-T20-C-A | General Electric |

| DS200UCPBG6A | General Electric | SGLA36AT0400 | General Electric |

| IC694BEM331CA | General Electric | UR 8FH | General Electric |

| IC697CMM711 | General Electric | IC697PWR711 | General Electric |

| 469-P5-HI-A20-E | General Electric | IC697CPX928 | General Electric |

| TB43400AF14 | General Electric | IC697BEM742 | General Electric |

| CR120B 022 02 | General Electric | IS200VRTDH1D | General Electric |

| FT-084 | General Electric | IC200ALG240 | General Electric |

| UR 7HH | General Electric | IC200CHS022 | General Electric |

| IS220PAICH2A | General Electric | IC200PWR001 | General Electric |

| IS200WROBH1A | General Electric | PRCZ11 | General Electric |

| IS200STAIH2ABB | General Electric | SFLA36A10250 | General Electric |

| IC660BBD024 | General Electric | IC200GBI001 | General Electric |

| IS200STAOH2AAA | General Electric | IC697RCM711 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC693PWR331 | General Electric |

| UR 7HH | General Electric | IC693CPU374 | General Electric |

| IS220PAICH2A | General Electric | 55-154607G041 | General Electric |

| IS200WROBH1A | General Electric | 55-186556G0041 | General Electric |

| IS200STAIH2ABB | General Electric | UR 8FH | General Electric |

| IC660BBD024 | General Electric | KYPDACGP1 | General Electric |

| IS200STAOH2AAA | General Electric | UR 6UH | General Electric |

| 469-P5-HI-A20-T-H | General Electric | UR 6DH | General Electric |

| IC694ALG221 | General Electric | SKPA 36AT 1200 | General Electric |

| 8851-LC-MT | General Electric | UR RHH | General Electric |

| SFLA36A10250 | General Electric | IC697CPX928 | General Electric |

| CE693PWR330 | General Electric | IC697CMM742 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC697BEM742 | General Electric |

| P9XPNNG | General Electric | IC697RCM711 | General Electric |

| P9XPNNG | General Electric | 369-HI-R-0-0-0-0-E | General Electric |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: