Description

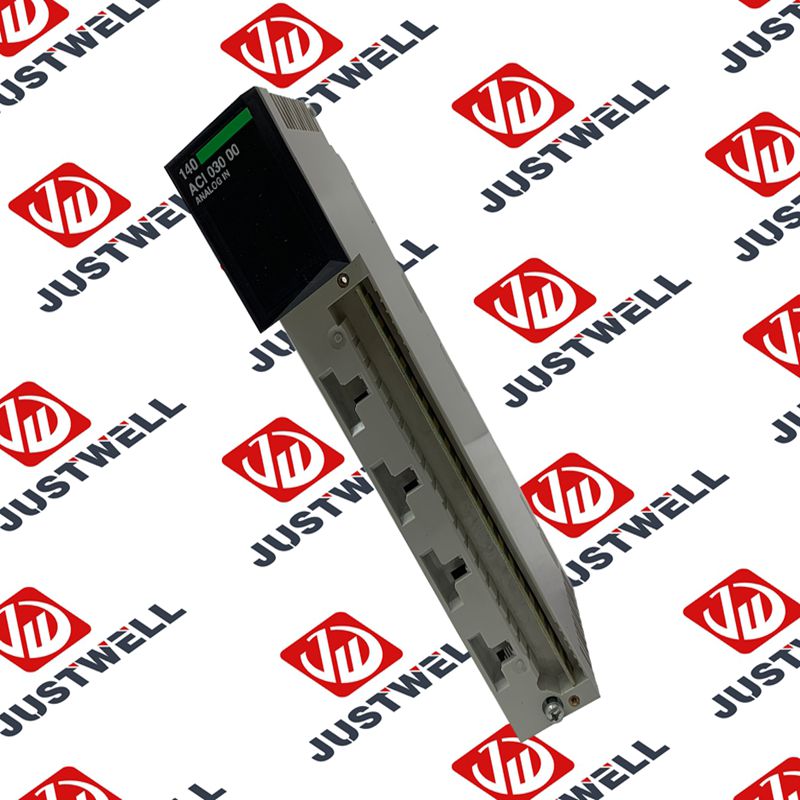

IC695PSD140 General Electric Controller module

Product Dimensions:

Product Description

GE Controller Modules are highly advanced, purpose-built electronic devices designed to manage and automate complex industrial processes. Unlike power modules that handle the flow of electricity, controller modules are the “brains” of a system. They receive inputs from sensors, process data according to a programmed logic, and generate outputs to control various actuators, motors, and power modules. These controllers are engineered for high reliability and are often used in mission-critical applications where precise control and real-time response are essential. They typically feature a robust design to withstand harsh industrial environments, including wide temperature ranges, vibration, and electrical noise.

Product Specifications

The specific parameters of GE Controller Modules vary depending on the model and its intended use, but common specifications include:

- Processor Type: The type and speed of the central processing unit (CPU), which determines the module’s processing power and speed.

- Memory: The amount of RAM and non-volatile memory for storing programs and data. This can range from a few megabytes to several gigabytes.

- I/O (Input/Output) Capacity: The number and type of input and output channels (e.g., analog, digital, high-speed). This determines how many sensors and actuators the module can interface with.

- Communication Protocols: The communication standards supported, such as Ethernet/IP, Profibus, Modbus, and PROFINET, which allow the module to communicate with other devices and systems.

- Programming Language: The languages supported for programming the control logic, typically IEC 61131-3 languages (Ladder Diagram, Structured Text, etc.).

- Redundancy: Some high-end modules offer redundant processors and power supplies for continuous operation in critical applications.

- Operating Environment: The specified temperature range, humidity, and vibration resistance.

Product Advantages

Using GE Controller Modules offers several key benefits for industrial automation and control:

- High Performance and Reliability: They are built with industrial-grade components and robust designs, ensuring long-term reliability and stability in demanding environments.

- Scalability and Flexibility: Many systems are modular, allowing users to add or remove I/O modules and other components as their needs change, providing a flexible and scalable solution.

- Advanced Functionality: GE controller modules often include advanced features like integrated motion control, advanced diagnostics, and cybersecurity capabilities, simplifying complex automation tasks.

- Seamless Integration: Designed to work seamlessly with other GE products and a wide range of third-party devices, they simplify system integration and reduce compatibility issues.

- Enhanced Safety: The modules often incorporate safety features and certifications, such as TUV or SIL (Safety Integrity Level) ratings, making them suitable for safety-critical applications.

- Simplified Programming: They are typically supported by powerful and user-friendly software platforms that simplify the development, testing, and deployment of control applications.

Product Applications

GE Controller Modules are essential components in a variety of industries and applications, including:

- Power Generation: They are used to control and monitor power plants, including gas turbines, steam turbines, and hydro plants.

- Oil & Gas: Used in upstream, midstream, and downstream operations for process control, pipeline monitoring, and safety systems.

- Manufacturing & Automation: They serve as the central control unit for assembly lines, robotic systems, and other automated manufacturing processes.

- Water & Wastewater Treatment: Controllers manage the entire treatment process, from pumping and filtering to chemical dosing and monitoring.

- Mining: Used for controlling and automating a wide range of mining equipment and processes, including conveyors and crushers.

- Transportation: Essential for railway signaling and control systems, as well as marine vessel automation.

Precautions

To ensure the longevity and reliable operation of GE Controller Modules, consider these precautions:

- Proper Installation: Mount the module in a clean, dry, and well-ventilated enclosure. Ensure proper grounding and wire management to prevent electrical noise and interference.

- Power Supply: Use a stable and correctly sized power supply unit. Fluctuations in voltage can damage the module’s sensitive electronic components.

- Environmental Conditions: Do not operate the module outside of its specified temperature, humidity, and vibration ranges. Extreme conditions can lead to performance degradation or failure.

- Software and Firmware: Regularly update the firmware and use the latest software versions for programming and configuration to ensure optimal performance and security.

- Cybersecurity: Implement robust cybersecurity measures, such as access control and network segmentation, to protect the controller and the entire system from unauthorized access.

- Documentation: Always refer to the product’s official manual and technical documentation for detailed installation, programming, and troubleshooting guidelines.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| IC660BBA025 | General Electric | 469-P5-HI-A20-T-H | General Electric |

| CR104PSG92B11 | General Electric | Multilin PQMII-T20-C-A | General Electric |

| DS200UCPBG6A | General Electric | SGLA36AT0400 | General Electric |

| IC694BEM331CA | General Electric | UR 8FH | General Electric |

| IC697CMM711 | General Electric | IC697PWR711 | General Electric |

| 469-P5-HI-A20-E | General Electric | IC697CPX928 | General Electric |

| TB43400AF14 | General Electric | IC697BEM742 | General Electric |

| CR120B 022 02 | General Electric | IS200VRTDH1D | General Electric |

| FT-084 | General Electric | IC200ALG240 | General Electric |

| UR 7HH | General Electric | IC200CHS022 | General Electric |

| IS220PAICH2A | General Electric | IC200PWR001 | General Electric |

| IS200WROBH1A | General Electric | PRCZ11 | General Electric |

| IS200STAIH2ABB | General Electric | SFLA36A10250 | General Electric |

| IC660BBD024 | General Electric | IC200GBI001 | General Electric |

| IS200STAOH2AAA | General Electric | IC697RCM711 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC693PWR331 | General Electric |

| UR 7HH | General Electric | IC693CPU374 | General Electric |

| IS220PAICH2A | General Electric | 55-154607G041 | General Electric |

| IS200WROBH1A | General Electric | 55-186556G0041 | General Electric |

| IS200STAIH2ABB | General Electric | UR 8FH | General Electric |

| IC660BBD024 | General Electric | KYPDACGP1 | General Electric |

| IS200STAOH2AAA | General Electric | UR 6UH | General Electric |

| 469-P5-HI-A20-T-H | General Electric | UR 6DH | General Electric |

| IC694ALG221 | General Electric | SKPA 36AT 1200 | General Electric |

| 8851-LC-MT | General Electric | UR RHH | General Electric |

| SFLA36A10250 | General Electric | IC697CPX928 | General Electric |

| CE693PWR330 | General Electric | IC697CMM742 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC697BEM742 | General Electric |

| P9XPNNG | General Electric | IC697RCM711 | General Electric |

| P9XPNNG | General Electric | 369-HI-R-0-0-0-0-E | General Electric |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: