Description

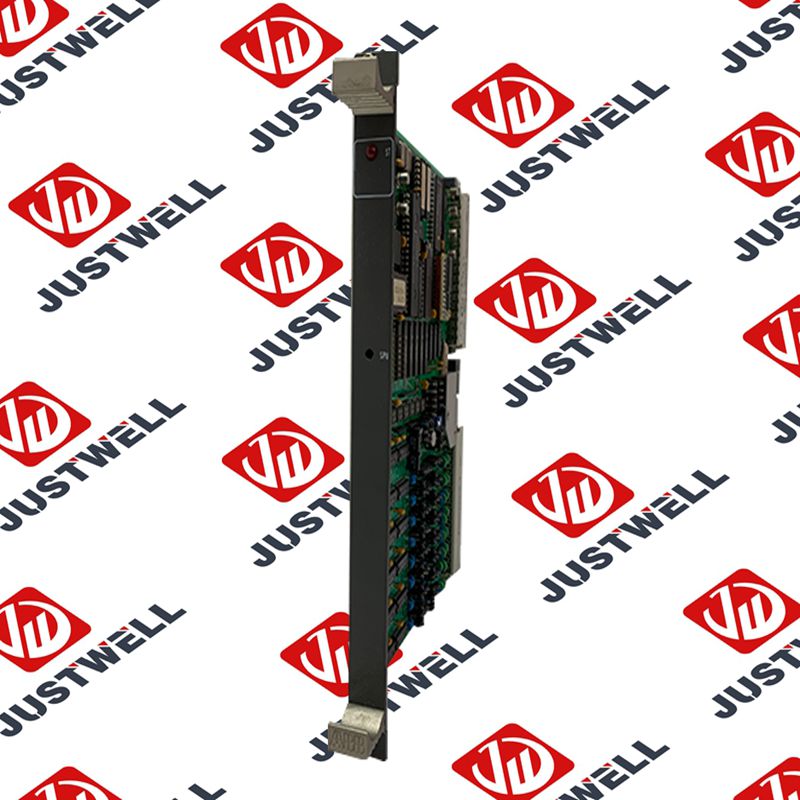

IS420ESWBH3A General Electric Programmable controller

Product Dimensions:

Product Description

GE Programmable Controllers, also known as Programmable Logic Controllers (PLCs), are rugged, industrial-grade computers designed to automate and control machine processes. They are the cornerstone of industrial automation, providing a reliable and robust solution for controlling everything from simple assembly line operations to complex, synchronized manufacturing processes. Unlike general-purpose computers, GE Programmable Controllers are built to withstand the harsh conditions of industrial environments, including extreme temperatures, vibration, dust, and electrical noise. They are modular systems, consisting of a processor module (the “brain”), I/O modules (for connecting to sensors and actuators), and a power supply, all housed within a single rack or chassis.

Product Specifications

Specifications for GE Programmable Controllers can vary widely by series and model. Key parameters typically include:

- Processor Performance: The speed and power of the CPU, measured by its scan time (how quickly it executes the program). High-performance models can handle complex calculations and large amounts of data in real-time.

- I/O Capacity: The total number of I/O points (inputs and outputs) the system can support, which determines the number of devices it can monitor and control. This can range from a few dozen to several thousand.

- Memory: The amount of memory for storing the control program, data logs, and firmware. Both RAM (for execution) and non-volatile memory (for permanent storage) are key.

- Communication Protocols: Support for various industrial communication standards like Ethernet/IP, Modbus, PROFINET, and others, allowing the controller to communicate with other PLCs, HMIs (Human-Machine Interfaces), and enterprise systems.

- Programming Languages: The standards supported for developing control logic, typically based on IEC 61131-3, which includes Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), and Sequential Function Chart (SFC).

- Redundancy and High Availability: Many GE controllers offer redundancy options (e.g., hot standby) for critical applications to ensure continuous operation and minimize downtime.

- Environmental Ratings: Specifications for the operating temperature range, humidity, and resistance to shock and vibration, which are crucial for industrial use.

Product Advantages

GE Programmable Controllers are a preferred choice for industrial automation for several reasons:

- Robustness and Reliability: They are engineered for continuous operation in demanding environments, offering a higher level of reliability than standard computers. This minimizes unexpected downtime and maintenance costs.

- Modularity and Scalability: The modular design allows you to customize the system by adding or removing I/O and communication modules as your needs evolve. This makes it a flexible and cost-effective solution for growing operations.

- Simplified Troubleshooting: The systems provide comprehensive diagnostic tools and status indicators that make it easier for technicians to identify and resolve issues, reducing troubleshooting time.

- Real-Time Performance: They are designed for deterministic, real-time control, which is essential for applications requiring precise timing and synchronized actions.

- Integrated Solutions: They are part of a broader portfolio of GE automation products, which ensures seamless integration with GE drives, HMI panels, and other components, simplifying system design and deployment.

- Cybersecurity: Modern GE controllers incorporate advanced cybersecurity features to protect against unauthorized access and cyber threats, which is increasingly important in connected industrial environments.

Product Applications

GE Programmable Controllers are used across a vast range of industries and applications, including:

- Manufacturing: Used to control robots, conveyor belts, packaging machines, and entire assembly lines.

- Oil & Gas: They manage processes in refineries, pipelines, and offshore platforms, handling everything from pump control to emergency shutdown systems.

- Water & Wastewater Treatment: They automate the entire treatment process, from water intake and filtration to chemical dosing and distribution.

- Power Generation: Used to control and monitor power plant systems, including gas turbines, steam turbines, and switchgear.

- Automotive: Essential for body shops, paint shops, and final assembly lines, ensuring precise and repeatable processes.

- Food & Beverage: They control batching, mixing, and bottling processes, ensuring consistency and quality.

Precautions

To ensure the safety and longevity of your GE Programmable Controller, keep the following precautions in mind:

- Proper Installation: Mount the controller in a clean, dry, and well-ventilated enclosure. Ensure proper grounding and wire management to minimize electrical interference.

- Power Supply Stability: Use a stable and correctly sized power supply. Voltage fluctuations or power spikes can damage the electronic components.

- Environmental Limits: Do not operate the controller outside of its specified temperature, humidity, and vibration ratings. Use climate control if necessary to stay within the recommended range.

- Firmware and Software: Always use the latest firmware from GE and keep your programming software updated. This ensures access to the latest features, security patches, and performance improvements.

- Backup Your Program: Always maintain a recent backup of your control program. This is critical for quick recovery in case of hardware failure or accidental data corruption.

- Security: Implement strong access controls and follow cybersecurity best practices to protect the controller and the network from unauthorized access.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| IC660BBA025 | General Electric | 469-P5-HI-A20-T-H | General Electric |

| CR104PSG92B11 | General Electric | Multilin PQMII-T20-C-A | General Electric |

| DS200UCPBG6A | General Electric | SGLA36AT0400 | General Electric |

| IC694BEM331CA | General Electric | UR 8FH | General Electric |

| IC697CMM711 | General Electric | IC697PWR711 | General Electric |

| 469-P5-HI-A20-E | General Electric | IC697CPX928 | General Electric |

| TB43400AF14 | General Electric | IC697BEM742 | General Electric |

| CR120B 022 02 | General Electric | IS200VRTDH1D | General Electric |

| FT-084 | General Electric | IC200ALG240 | General Electric |

| UR 7HH | General Electric | IC200CHS022 | General Electric |

| IS220PAICH2A | General Electric | IC200PWR001 | General Electric |

| IS200WROBH1A | General Electric | PRCZ11 | General Electric |

| IS200STAIH2ABB | General Electric | SFLA36A10250 | General Electric |

| IC660BBD024 | General Electric | IC200GBI001 | General Electric |

| IS200STAOH2AAA | General Electric | IC697RCM711 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC693PWR331 | General Electric |

| UR 7HH | General Electric | IC693CPU374 | General Electric |

| IS220PAICH2A | General Electric | 55-154607G041 | General Electric |

| IS200WROBH1A | General Electric | 55-186556G0041 | General Electric |

| IS200STAIH2ABB | General Electric | UR 8FH | General Electric |

| IC660BBD024 | General Electric | KYPDACGP1 | General Electric |

| IS200STAOH2AAA | General Electric | UR 6UH | General Electric |

| 469-P5-HI-A20-T-H | General Electric | UR 6DH | General Electric |

| IC694ALG221 | General Electric | SKPA 36AT 1200 | General Electric |

| 8851-LC-MT | General Electric | UR RHH | General Electric |

| SFLA36A10250 | General Electric | IC697CPX928 | General Electric |

| CE693PWR330 | General Electric | IC697CMM742 | General Electric |

| 469-P5-HI-A20-T-H | General Electric | IC697BEM742 | General Electric |

| P9XPNNG | General Electric | IC697RCM711 | General Electric |

| P9XPNNG | General Electric | 369-HI-R-0-0-0-0-E | General Electric |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: