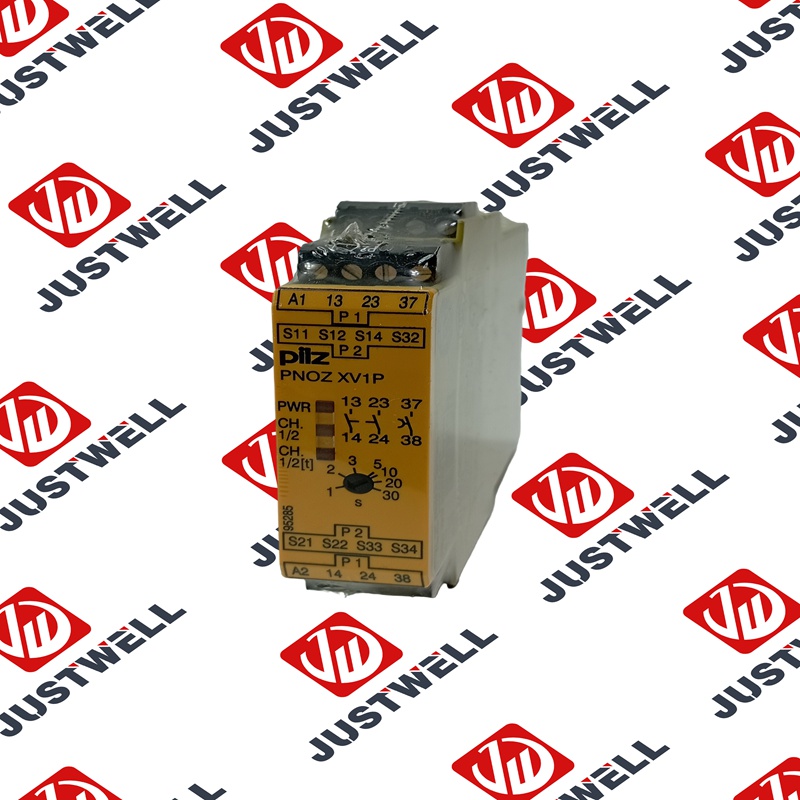

Description

PNOZ XV1P Pilz Interface module

Product Dimensions:

Product Description

The Pilz PNOZ XV1P is a versatile safety relay from the PNOZsigma/PNOZpower family, designed to provide high-level safety monitoring with the added benefit of adjustable time-delay functionality. It is widely used for applications requiring a controlled stop (Category 1) or delayed safety responses.

Product Parameters

The PNOZ XV1P is characterized by its ability to manage both instantaneous and time-delayed safety contacts.

| Feature | Specification |

| Safety Level | SIL 3 (IEC 61508), PL e (Cat. 4) |

| Supply Voltage | 24 V DC or 24–240 V AC/DC (model dependent) |

| Instantaneous Contacts | 2 Safety Contacts (N/O) |

| Time-Delay Contacts | 1 Safety Contact (N/O) |

| Delay Time Range | Adjustable (e.g., 0.1s to 3s, 0s to 30s depending on version) |

| Input Channels | 1-channel or 2-channel wiring |

| Reset Types | Automatic, Manual, or Monitored manual reset |

| Housing Width | 22.5 mm |

| Terminal Type | Plug-in screw or spring-loaded terminals |

Key Product Advantages

-

Adjustable Delay: Allows machines to complete a cycle or perform a “Stop Category 1” (controlled braking) before power is completely removed from the actuators.

-

Dual Safety Logic: Provides both instantaneous contacts (for immediate shutoff) and delayed contacts (for braking or sequential shutdown) in one compact unit.

-

High Reliability: Meets the highest safety standards (PL e / SIL 3), ensuring maximum protection for personnel and machinery.

-

Modular Terminals: Features plug-in terminals that simplify installation and allow for rapid replacement without rewiring errors.

-

Comprehensive Monitoring: Built-in detection for shorts across contacts, earth faults, and open circuits.

Product Applications

-

Stop Category 1 Functions: Used where a machine must be brought to a halt in a controlled manner (e.g., using a brake) before the safety gates are unlocked.

-

E-Stop Monitoring: Managing emergency stop buttons where certain auxiliary equipment needs a few seconds to shut down safely.

-

Safety Gates with Interlocks: Delaying the release of a locking mechanism until the hazardous motion has completely ceased.

-

Packaging and Conveyors: Synchronizing the shutdown of multiple belt segments to prevent product pile-ups during an emergency stop.

Important Usage Notes (Precautions)

-

Time Setting: Ensure the delay time is set correctly according to the machine’s risk assessment. If the time is too short, the hazard may still exist when the contact opens; if too long, it may increase risk in other ways.

-

Feedback Loop: When using external contactors, the feedback loop (S12/S34) must be correctly wired to ensure the relay cannot be reset if a contactor is welded shut.

-

Reset Configuration: Choosing between Automatic and Monitored Manual reset is critical. For most dangerous machinery, a Monitored Manual reset is required to prevent an unexpected restart.

-

Mounting: Install the unit in a control cabinet with at least IP54 protection. Ensure adequate spacing if multiple relays are mounted together to manage heat.

Wiring Logic Overview

-

S11/S12 & S21/S22: Input channels for E-stop or safety gate switches.

-

13-14, 23-24: Instantaneous safe outputs.

-

37-38: Time-delayed safe output.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| 312070 | PILZ |

| PSS1BMP | PILZ |

| PSS1 PS 24 | PILZ |

| PSS1 DI 2 | PILZ |

| S24230-A138-A1-08 | PILZ |

| S1MN 24VAC/DC/2C/O | PILZ |

| PZE 9 24VDC 8N/O 1N/C | PILZ |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: