Description

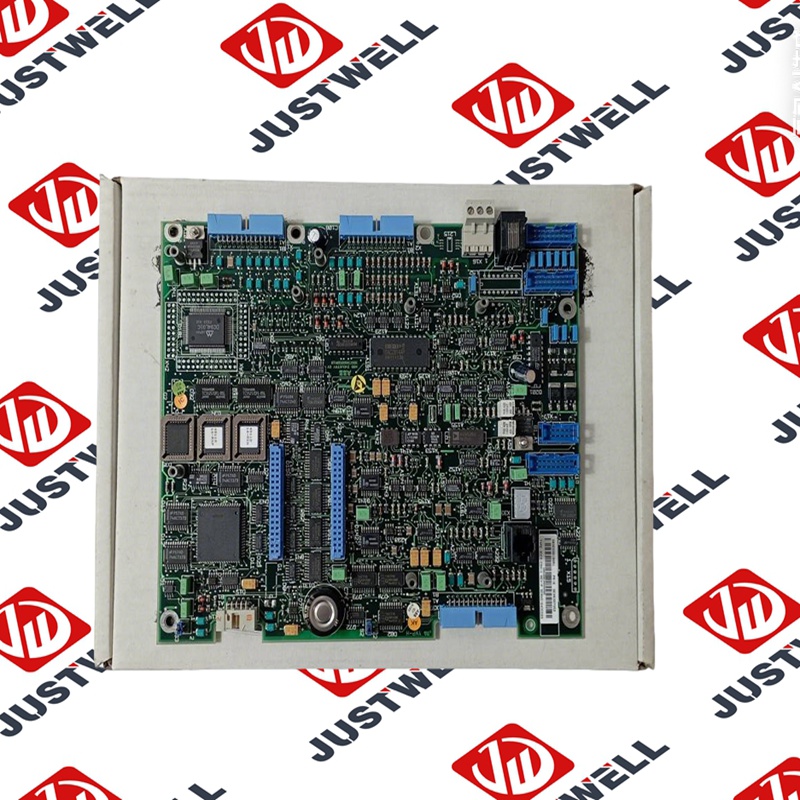

SDCS-CON-1 ABB Multifunctional Processor Module

Product Dimensions:

Product Description

The ABB SDCS-CON-1 is the core microprocessor-based control board found in older generations of ABB’s high-performance DC drive converters. It is the component responsible for all control, regulation, and communication tasks within the drive system.

-

Type: Microprocessor-based Control Board / Control Unit.

-

Function: It executes the drive’s control software, performing tasks such as:

-

Current, speed, and torque control loops.

-

Field weakening control.

-

Sequence control (starting, stopping, reversing).

-

Fault diagnostics and protection.

-

Communication interfacing.

-

-

Design: The board contains the primary CPU, memory, internal communication logic, and the interface points for connecting external I/O and communication modules (which typically plug into the SDCS-CON-1).

-

Role: It manages the firing angles of the drive’s thyristor bridge to accurately control the voltage and current supplied to the DC motor.

Product Specifications

As a component of a larger drive system, the SDCS-CON-1 specifications relate to its processing and interfacing capabilities.

| Feature | Specification |

| Model | SDCS-CON-1 |

| Product Family | ABB DC Drives (DCS500 series, other legacy models) |

| Processor | High-speed industrial microprocessor for real-time control. |

| Control Principle | Digital control of the thyristor bridge. |

| I/O Interface | Connectors for Analog I/O and Digital I/O via dedicated expansion boards. |

| Communication | Serial ports for parameter setting (e.g., via PC or HMI). |

| Programming | Configurable via ABB’s specific drive configuration software (e.g., DriveWindow). |

| Control Logic | Executes drive sequence logic and application programs. |

| Operating Environment | Designed for industrial control panel environments. |

Product Advantages

-

Reliable Legacy Performance: Although an older product, the SDCS-CON-1 was engineered for high reliability and stability, crucial for continuous industrial processes.

-

Precise DC Control: It provides excellent dynamic performance for DC motor applications, enabling precise regulation of speed and torque necessary for critical machinery.

-

Modular Design: Its design allows for the addition of different I/O and communication modules to be plugged directly onto the main control board, offering a degree of customization.

-

Robust Diagnostics: Features comprehensive on-board diagnostics and fault logging capabilities, which help maintenance staff quickly identify and resolve drive issues.

-

Upgrade Path: As a modular component, it was designed with defined interfaces, easing the transition and upgrade path to newer ABB control platforms (like the SDCS-CON-3, DCS800 series).

Precautions

-

ESD Protection: The SDCS-CON-1 is highly susceptible to Electrostatic Discharge (ESD). Always use anti-static wrist straps and follow standard ESD control procedures when handling the board to prevent catastrophic failure.

-

Parameter Backup: Before replacing or removing the board, ensure that all drive parameters are securely backed up. The new board requires the correct parameter set to function correctly with the motor and machine.

-

System Compatibility: Ensure the firmware version and hardware revision of the replacement SDCS-CON-1 are fully compatible with the specific model of the ABB drive unit (DCS500 or others) it is installed in.

-

Power Down Procedure: Always de-energize and lock out all power (main and auxiliary) to the drive before inserting or removing the control board or any attached I/O modules.

-

Ribbon Connectors: Be meticulous when connecting internal ribbon cables to the board’s connectors, as improper alignment can easily bend pins and cause permanent damage.

Product Applications

The SDCS-CON-1 was primarily used in industrial applications that relied on high-power DC drives for continuous, high-performance operation.

-

Rolling Mills: Used to control the speed and tension of material through hot and cold steel or aluminum rolling processes.

-

Wire and Cable Industry: Managing synchronized speed and tension control for winding, spooling, and drawing machines.

-

Paper Machines: Controlling sections of the paper machine (e.g., wet end, dryer) where precise speed control is essential for web tension.

-

Test Benches: Providing high-accuracy speed and torque control for industrial motor and component testing rigs.

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| SD834 | ABB | EI813F | ABB |

| CI810B | ABB | AM801F | ABB |

| TB810 | ABB | SD812F | ABB |

| TK811V050 | ABB | AM811F | ABB |

| TB842 | ABB | TK802F | ABB |

| TB40A | ABB | PM803F | ABB |

| AO845A | ABB | FI820F | ABB |

| AO801 | ABB | FI810F | ABB |

| DI801 | ABB | EI803F | ABB |

| DO801 | ABB | SA801F | ABB |

| DI811 | ABB | SA811F | ABB |

| AI810 | ABB | SB808F | ABB |

| AI830A | ABB | FI830F | ABB |

| DP840 | ABB | SD802F | ABB |

| AO845A | ABB | AM895F | ABB |

| AI835A | ABB | SY809F | ABB |

| DO810 | ABB | EI812F | ABB |

| TB820V2 | ABB | EI811F | ABB |

| AO810V2 | ABB | RLM01 | ABB |

| AI820 | ABB | PM902F | ABB |

| DI821 | ABB | CI930F | ABB |

| AO820 | ABB | CP430B | ABB |

| DO802 | ABB | CP430T | ABB |

| CI801 | ABB | CP450T | ABB |

| DI810 | ABB | CP450T-ETH | ABB |

| AI845 | ABB | CP620 | ABB |

| AI801 | ABB | 07KT95 | ABB |

| DI803 | ABB | 07CR41 | ABB |

| DI802 | ABB | 07DC92 | ABB |

| TB40A | ABB | 07DI92 | ABB |

| CI840A | ABB | XI16E1 | ABB |

| TB825 | ABB | 07KP53 | ABB |

| BC810K02 | ABB | 07AI91 | ABB |

| PM866K02 | ABB | 3BSE018168R1 | ABB |

| PM861AK02 | ABB | 07KT98 | ABB |

| TB852 | ABB | 1SAP520100R0001 | ABB |

| PM851AK01 | ABB | GJR5252800R0100 | ABB |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: