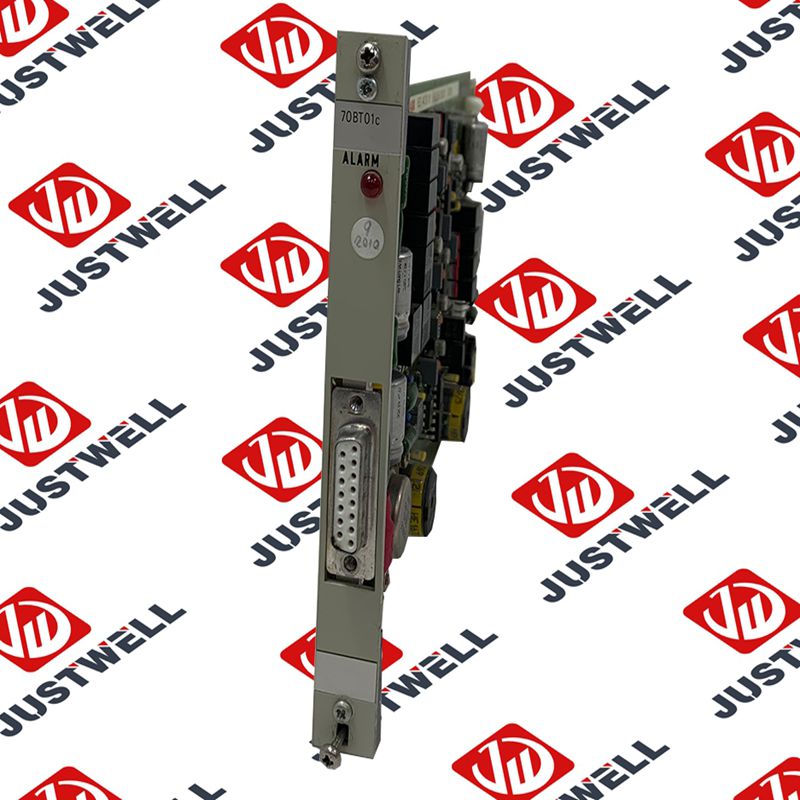

Description

TAC Xenta 301 SCHNEIDER Simulation output module

Product Dimensions:

Product Description

The TAC Xenta 301 is a member of the Xenta 300 series of high-performance, programmable automation controllers. It is a standalone field controller that integrates into a LonWorks-based Building Management System (BMS).

-

Type: LonWorks Network Variable (NV) Programmable Controller.

-

Function: It executes a custom control application developed using the TAC Menta® graphical programming tool. Its I/O configuration is optimized for applications requiring extensive on/off control and status monitoring, such as sequence control, interlocks, or driving large banks of relays.

-

Networking: It uses the LonWorks (LonMark) protocol for robust and peer-to-peer data exchange with other controllers, I/O modules (like Xenta 421/422), sensors, and the building supervisor.

-

I/O Configuration: The Xenta 301 is characterized by having a higher ratio of Digital Outputs (DOs) (relays) compared to the Xenta 302, making it ideal for systems with many two-position (on/off) valves, contactors, or fan stages.

Product Specifications

| Feature | Specification |

| Model | TAC Xenta 301 |

| Supply Voltage (Power) | 24 V AC $\pm$10%, 50/60 Hz |

| Power Consumption | Max 8 VA |

| Universal Inputs (UI) | 4 |

| Digital Inputs (DI) | 2 (Dedicated) |

| UI Types | Selectable for Thermistor, $0-10\,\text{V DC}$, $0-20\,\text{mA}$, Pulse Counting |

| Universal Outputs (UO) | 2 (Selectable as $0-10\,\text{V DC}$ Analog or $24\,\text{V AC}$ Digital Triac) |

| Digital Outputs (DO) | 6 (Relay Outputs) |

| DO Rating | Max 2 A, 250 V AC (Resistive load) |

| Total I/O Points | 14 (4 UI, 2 DI, 2 UO, 6 DO) |

| Communication | LonWorks (FTT-10A Transceiver) |

Product Advantages

-

DO-Optimized Configuration: With 6 Relay Outputs and 2 UOs (which can also be used as digital outputs), the Xenta 301 is a powerhouse for applications demanding numerous on/off commands, such as staged heating/cooling or complex interlocking sequences.

-

Standalone Control: Executes all control logic locally, ensuring that critical sequences and safety interlocks remain active even if communication with the supervisory network is temporarily lost.

-

LonWorks Integration: Provides reliable, standard-based peer-to-peer communication within the BMS network.

-

I/O Flexibility: The combination of Universal Inputs (monitoring) and configurable Universal Outputs (modulating or digital) allows it to handle a variety of control requirements.

-

Simplified Engineering: The use of the TAC Menta graphical programming environment streamlines the application development process.

Precautions

-

Programming Required: Like all Xenta controllers, the 301 is freely programmable and requires an application to be created and downloaded using the TAC Menta tool for it to function.

-

Relay Output Limits: The 6 Digital Outputs are relay contacts rated for a maximum of $2\,\text{A}$ and $250\,\text{V AC}$. Do not use them for direct control of high-current loads. Interposing relays or contactors must be used for any load exceeding these limits.

-

Universal Output Setting: Only 2 outputs are Universal Outputs (UO). Ensure they are correctly configured as either $0-10\,\text{V}$ (for modulating control) or Triac (for digital control) to prevent damage to the connected actuators or loads.

-

Network Addressing: Proper LonWorks configuration, including node addressing and network variable binding, is essential for successful communication with other system components.

-

Power Quality: Provide a stable $24\,\text{V AC}$ supply and verify transformer sizing to accommodate the controller and all connected field devices.

Product Applications

The Xenta 301 is typically applied in situations requiring many digital points for status, alarm, and control functions, often involving staging or sequence control.

-

Staged Equipment Control:

-

Controlling multi-stage heating elements or chillers/boilers, where multiple on/off outputs are needed for staging.

-

Managing multiple fan stages or interlocking dampers.

-

-

Pump and Valve Control:

-

Controlling banks of two-position valves (e.g., terminal unit hydronic control).

-

Controlling multiple primary/secondary pumps with sequencing logic (DOs).

-

-

Sequence/Interlock Applications (Simulation):

-

Used in applications requiring complex interlocking logic between various pieces of equipment, often involving a high number of digital status inputs and control outputs.

-

-

Medium Sized AHU Control:

-

Suitable for AHUs with multiple fan speeds and staged heating/cooling.

-

Shipping Port: Xiamen, China

Payment: Bank of Chicago, Bank of Singapore

Express cooperation: fedex, DHL, UPS and your express account

Service: Professional Sales provides 24 hours /7 days online service

Please make an inquiry for more models:

| A9V41363 | SCHNEIDER | ABL8FEQ24150 | SCHNEIDER |

| 140CPU67160 | SCHNEIDER | TBUP4B-102-01-0-1 | SCHNEIDER |

| ABL4RSM24100 | SCHNEIDER | NG125N C10A | SCHNEIDER |

| 140ACI03000 | SCHNEIDER | BMXDDI3202K | SCHNEIDER |

| 140OSI35300 | SCHNEIDER | BMXP342020 | SCHNEIDER |

| 140DVO85300 | SCHNEIDER | BMXDDO3202K | SCHNEIDER |

| A9F74402 | SCHNEIDER | BMXCRA31210 | SCHNEIDER |

| A9F79440 | SCHNEIDER | BMXXBP1200 | SCHNEIDER |

| A9A26927 | SCHNEIDER | BMXAMO0210 | SCHNEIDER |

| XVLA323 | SCHNEIDER | BMXNOR0200H | SCHNEIDER |

| ABL8MEM24006 | SCHNEIDER | BMXERT1604T | SCHNEIDER |

| ABLM1A24006 | SCHNEIDER | BMXEHC0800 | SCHNEIDER |

| A9F04104 | SCHNEIDER | ATV630D90N4 | SCHNEIDER |

| A9F74110 | SCHNEIDER | ZCMD21L08R12 | SCHNEIDER |

| A9F74220 | SCHNEIDER | TBUP4-102-01-0-0 | SCHNEIDER |

| A9F74216 | SCHNEIDER | 140CHS11000 | SCHNEIDER |

| 782XDXH21-24D | SCHNEIDER | 140CPU43412A | SCHNEIDER |

| SURT1000XLI | SCHNEIDER | 140CRP93200 | SCHNEIDER |

| SRT3000RMXLI | SCHNEIDER | 140DDI35300 | SCHNEIDER |

| LV529488 | SCHNEIDER | 140XBP01600 | SCHNEIDER |

| ABL1REM24025 | SCHNEIDER | TM200C40T | SCHNEIDER |

| XACA4913 | SCHNEIDER | TMCR2AM3 | SCHNEIDER |

| EGX150 | SCHNEIDER | TMCR2SL1A | SCHNEIDER |

Phone:

Phone:  Email:

Email:  WhatsApp:

WhatsApp: